ABOUT KMPROD

Industry 4.0 Use Case

Dive into our interactive infographic and discover how KmProd, developed by META 2i, has transformed the operational efficiency of an Aluminium Spinning plant through its advanced features. Explore step by step how our MES/MOM solution optimized production processes, improved material traceability, and strengthened quality in this specific industrial environment.

Infography complete

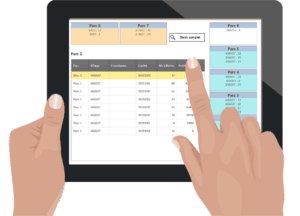

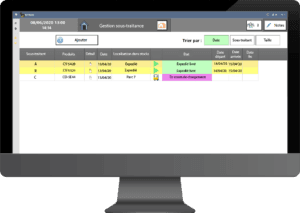

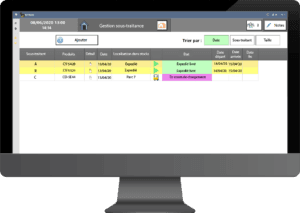

Commercial services - Online orders

KmProd scheduling gives your commercial department the neccesary monitoring

tools to check that production and delivery deadlines agreed upon with other

business units and clients are met. This will reassure your clients and will be one of

your major sales thus constituting a major sales argument.

KmProd offers an online ordering service for your customers. Orders are then

directly integrated into the KmProd system. Thus, you can offer your customers

reliable tracking solutions for their merchandise, as well as help them meet instant

deadlines.

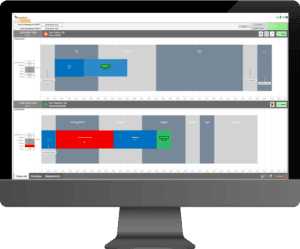

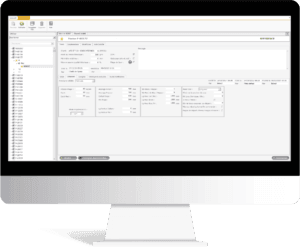

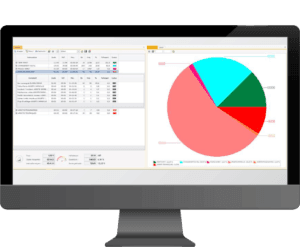

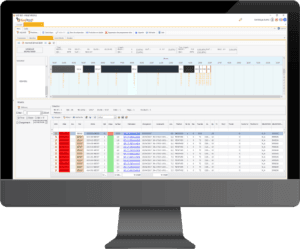

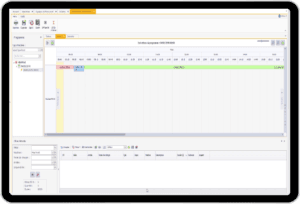

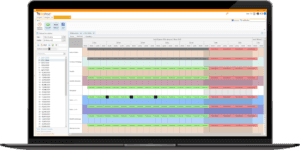

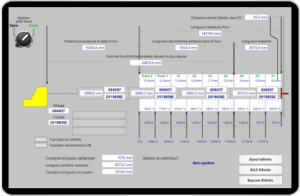

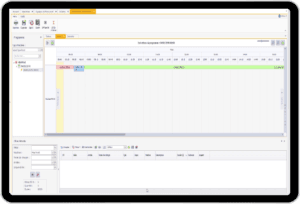

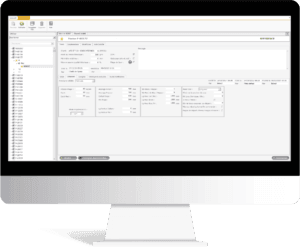

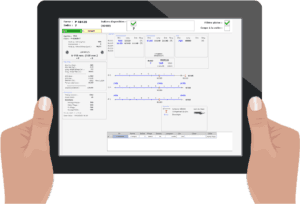

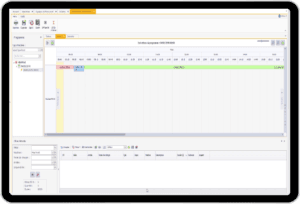

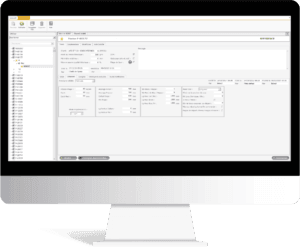

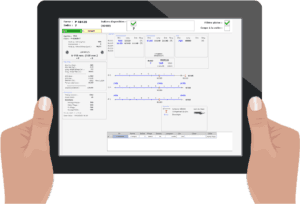

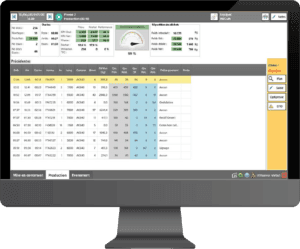

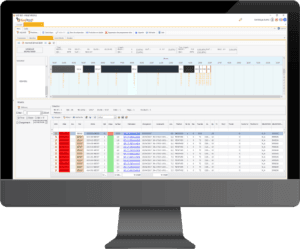

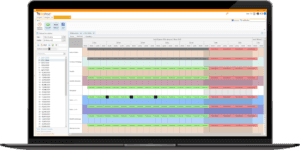

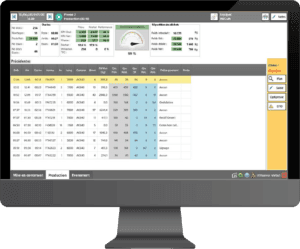

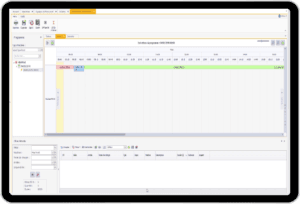

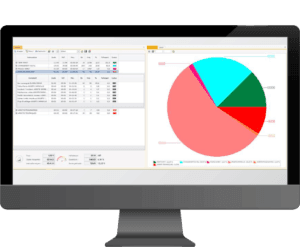

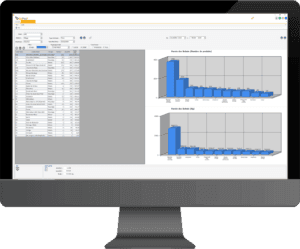

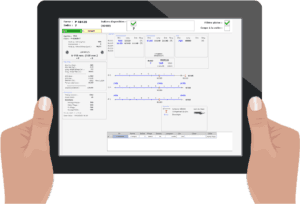

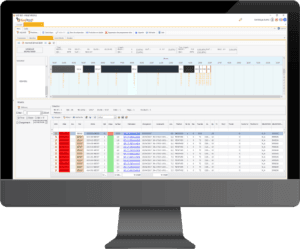

Production planning / Dashboard

KmProd is interfaced and synced with your ERP, from which all the

necessary data is retrieved. It therefore allows multiple approvals for

your offices including:

• A complete IS system

• Production planning

• Analytical Dashboards to measure your performance

• Production scheduling

• An item database

• Shipment management

• Machine planning

• Nomenclature

The production schedule is recalculated according to customer orders

to generate deadlines / screens.

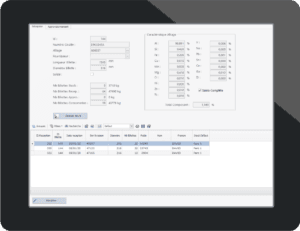

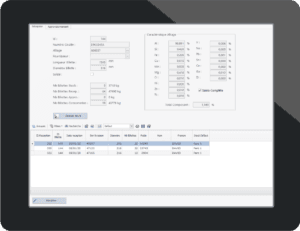

Supply Chain

KmProd allows the traceability of supplies at all scales:

Each billet is entered in the database and its position in

real time is visible on the application. KmProd helps

forecast and plan future supply needs based on

production. This effectively saves time as well as enables

a more fluid production process by limiting the storage of

billets.

Stocks

Our tool makes it possible to easily manage stocks by ensuring

a simple traceability of billets, according their suppliers, alloys,

castings, etc. It also enables you and your team to manage in real

time the filling of the various storage yards.

The calculation of your supply needs by KmProd is performed by

taking into account your planned production. Thus it allows a more

effective and fluid storage process. As we all know, a part that has

been ordered too early needs to be stored for too long, resulting in

a useless and costly waste of time and space.

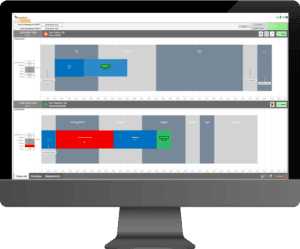

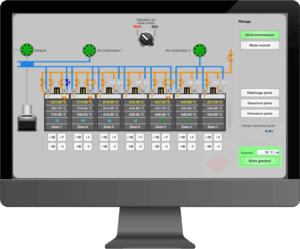

Kiln Management

KmProd is connected to your workshop equipment and can

give oven heating instructions.

It allows an analysis of the performance of the use of the ovens,

in order to achieve energy savings by optimizing the heating

time based on planned production.

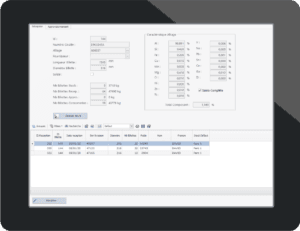

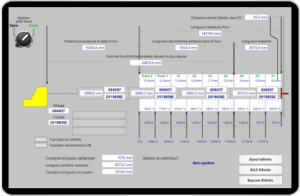

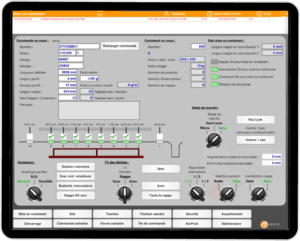

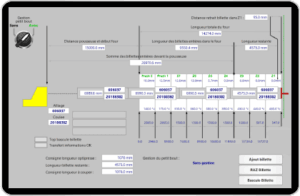

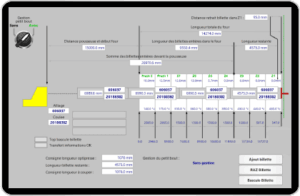

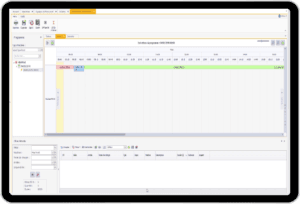

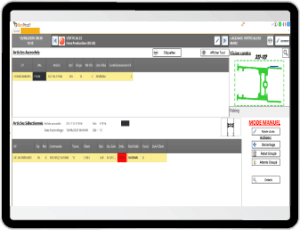

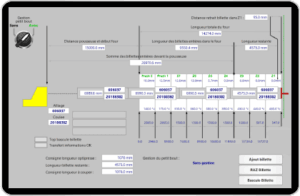

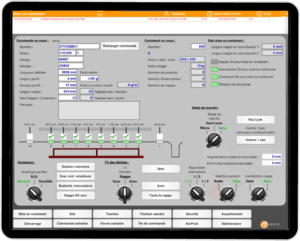

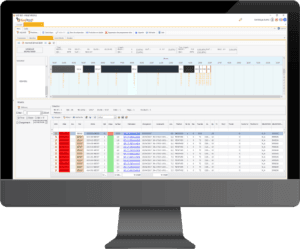

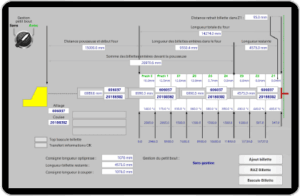

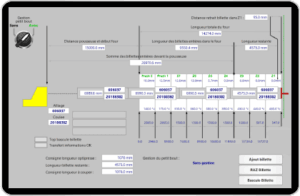

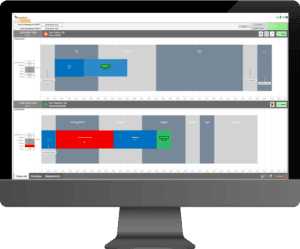

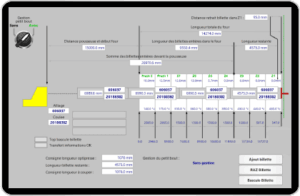

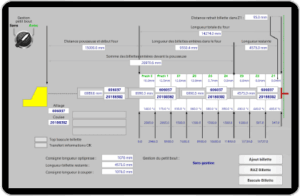

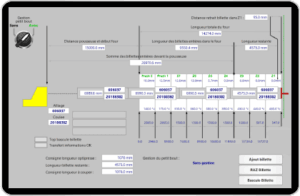

Billet Cutting

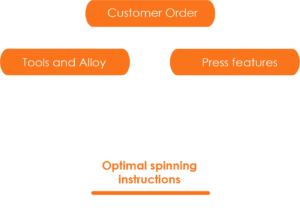

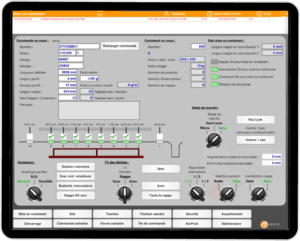

KmProd integrates an industrial intelligence module called

OptiPress which makes it possible to determine and calculate

the aluminum spinning instructions, and which optimizes the

cutting from the first cut of the billets.

It thus allows a reduction in rejects, and in the processing time.

It therefore allows savings at all scales !

Tool Store

• Production instructions / technical parameters

• Management and evaluation of supply chain suppliers

• Performance and condition

• Management of the chain furnace

• Adjustments / Maintenance / Tests

• KPI: Life expectancy, number of tests ...

• Store management

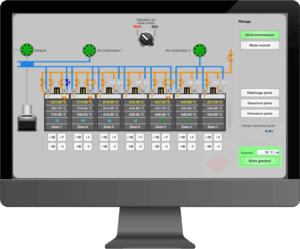

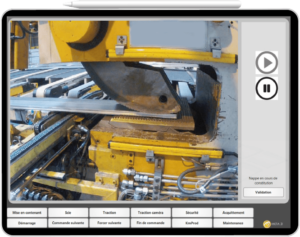

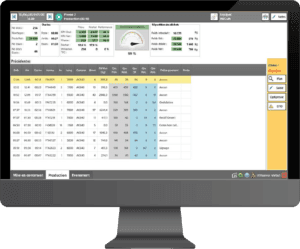

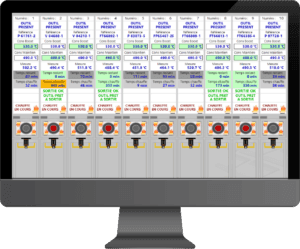

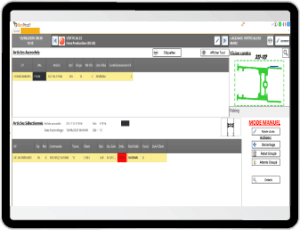

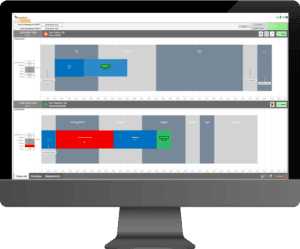

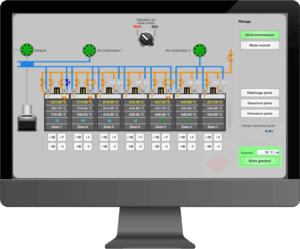

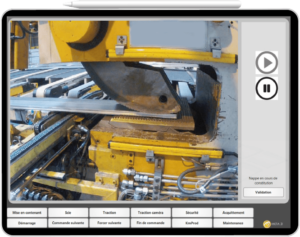

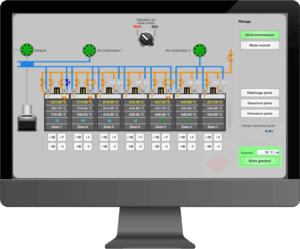

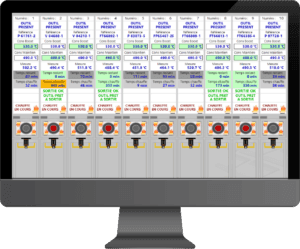

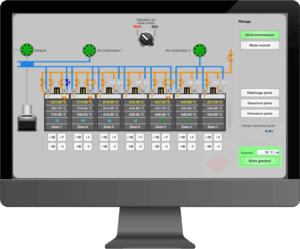

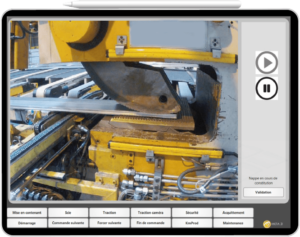

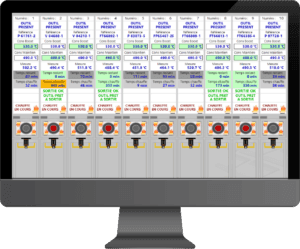

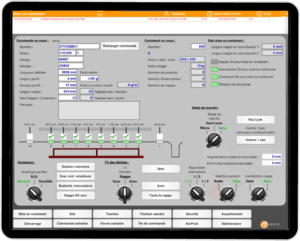

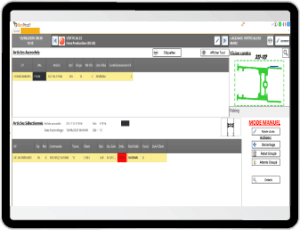

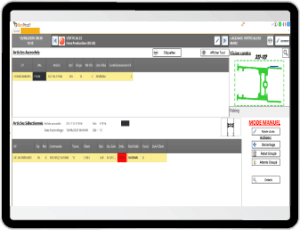

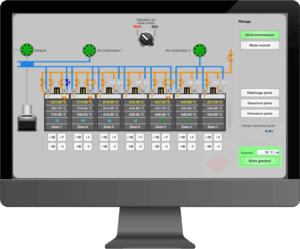

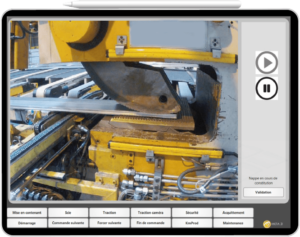

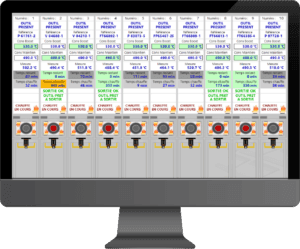

Press supervision

The KmProd solution allows complete control and supervision

of the press, in order to ensure that production is as efficient as

possible.

While fully knowing the state and operation of production tools

to be able to analyze its performance.

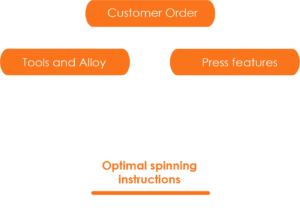

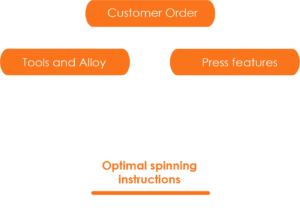

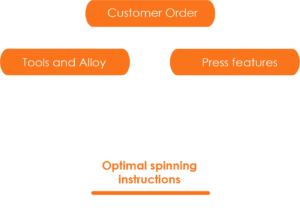

OptiPresse

OptiPresse is an industrial intelligence module that calculates

and determines the most efficient spinning instructions.

• Unique repository

• Artificial Intelligence

• Return on investment by reducing costs and waste.

• Computer Assisted Maintenance Management

• Organizational planning and forecasting

• Intuitive and improved maintenance planning

• Cost reduction

• Optimization of intervention times and times

• Extended equipment life expectancy

• Requests for automatic intervention

KmEnergy saves energy.

The tool shows where energy is lost.

• Water leak

• Heat loss

• Air conditioning

• Co2

• Overconsumption of electricity

Detection performed via machine learning algorithms

and analysis of energetic performance.

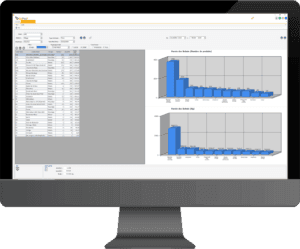

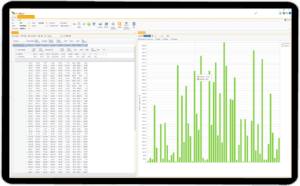

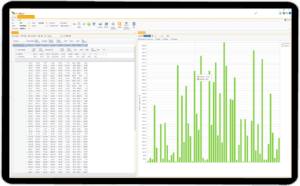

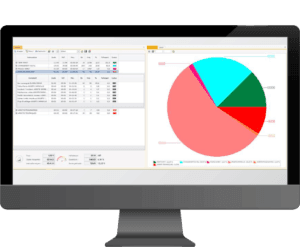

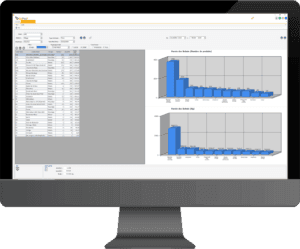

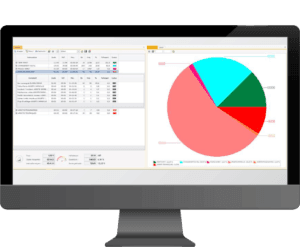

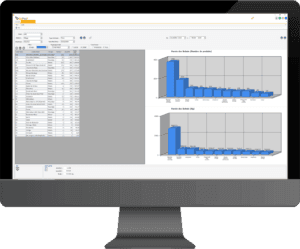

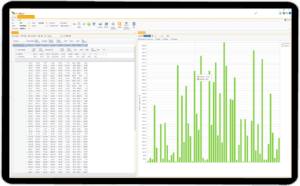

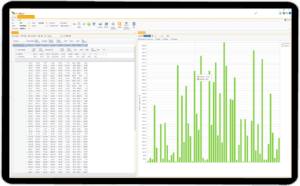

R&D

KmProd generates feedback that is essential for quality

control and its improvement in research and development

services.

Thus the data collected makes it possible to generate

statistics useful for the creation of future products and services.

Summaries and reports can be easily issued to accompany

the orientation resulting from the field feedback.

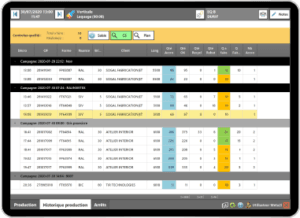

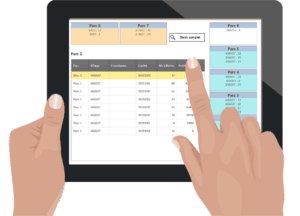

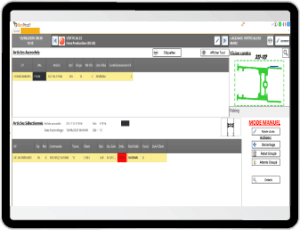

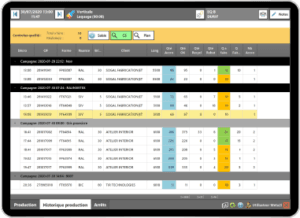

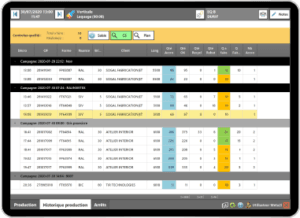

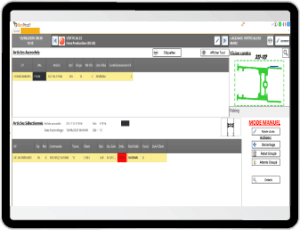

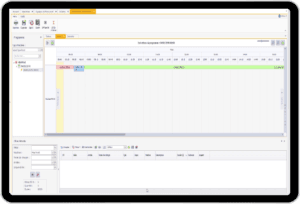

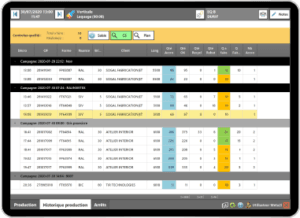

Workshop Management

KmProd generates pending production orders, production history

and events on a dedicated screen for your workshop's staff and

operators. They can also see their performance.

KmProd allows the operator to know where it is in production and

what to do.

The machine screen allows real-time supervision of machine

operation, as well as the implementation of preventive

maintenance to save time.

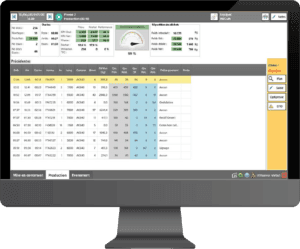

Quality control and rejects

KmProd makes it possible to limit rejects by optimizing offcuts

during cutting, and by automating quality control. But also to

analyze the quality performance (quality synthesis).

The rejects which are therefore limited and may be recycled

more easily, which allows savings at all levels.

Management of the income furnace

KmProd connects to the workshop equipment and can

give instructions for heating the furnaces.

It allows an analysis of the performance of the use of the

furnaces, in order to achieve energy savings by optimizing

time of heating according to the planned production.

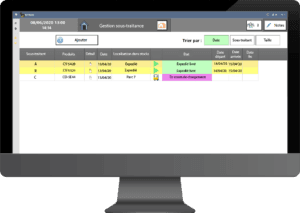

Subcontractor management

Our solution allows a simplified management of

contractors (logistics and / or industrial subcontracting).

The products are traceable throughout the process and

the organization is improved which saves time, lower losses,

and organized storage of finished or semi-finished products.

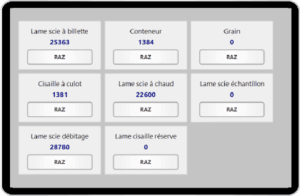

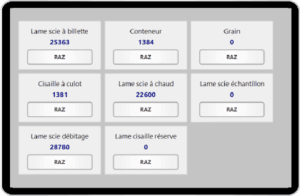

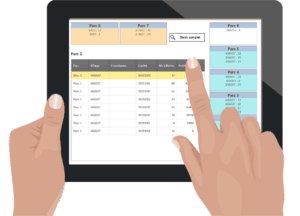

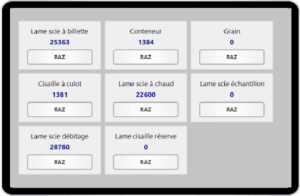

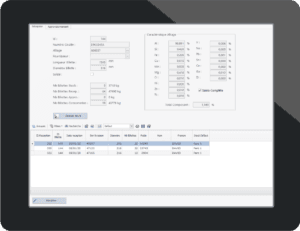

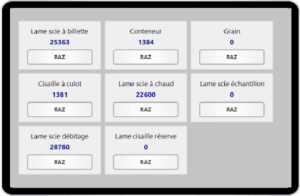

Container management

KmProd integrates a container management module enabling

real time efficient localization.

Each container is weighed to ensure that the content is the right

one, the characteristics of the profiles are directly associated with

the tool and are visible on the screen.

Avoiding errors will save time and improve your organizational

processes.

Equipment

KmProd allows you to forecast and plan which accessories

and equipment are going to be used in production.

This optimizes the load on the production line and saves

time for future operations.

Anodization

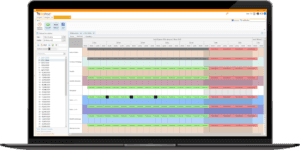

KmProd anodization makes it possible to manage what

type of product will be used for the anodization of the

profiles.

Based on Machine Learning and the industrial

intelligence algorithms developed by KmProd, the

anodization schedule optimizes deadlines and

increases productivity.

Lacquering

KmProd lacquering makes it possible forecast which type of

paint will be used to optimize the process and thus save time.

The lacquering schedule is organized by color shade, enabling

the optimiziation of the time allocated to the cleaning of cabins :

for example the light tones in one cab and the dark ones in the

other, the two cabins are therefore never cleaned at the same time!

This makes it possible to maximize the lacquering time of the profiles.

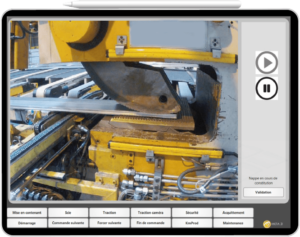

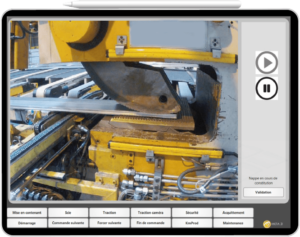

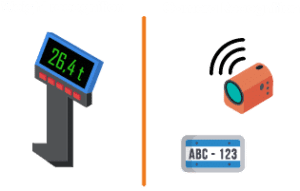

Camera Labeling

A camera recognition system identifies the shape of

the incoming profile, the correct label can then be

stuck on the product.

The error rate is drastically reduced thanks to process

automation, which also leads to significant increase

in performance.

Packaging

KmProd simplifies your production packaging process

thanks to a dedicated module.

A workshop screen allows the operator to know exactly

the stage his/her production process , what product is

to be made and how to pack it. The detailed vision of

the production process enables your team to identify

where improvement is needed to ensure the performance

possible.

The arrival of components from the same order is planned,

to avoid stocking products on site and to promote the

almost immediate shipment of orders.

Shipping and weighing

KmProd ensures the traceability of billet supplies until the

shipment of the profiles.

The management of the shipment is done by a schedule

shared with the transport subcontractor, which sends the

notifications to the customers who are waiting for their order.

The weighing of trucks before their departure can be carried

out to ensure a final check of the weight to avoid any errors

and save time.

Staff Management

KmProd ensures HR management within the workshop:

• Team planning by the workshop manager

• Workshop screen with input by the worker

• Event management (RTT, breaks, etc.)

• Calculation and analysis of worker performance

Foundry

KmProd allows you to monitor the entire production

flow of your workshop, starting from the foundry.

• Foundry Management

• Recycling of scrap

• Traceability of raw materials throughout the whole

production flow, according to metallurgical characteristics

Human

At the heart of your business and your intelligence, people are at the heart of KmProd’s approach to efficiency.

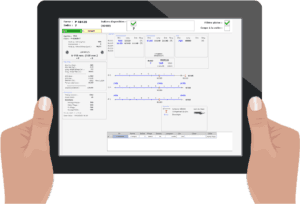

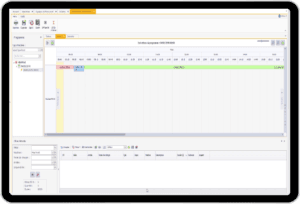

Production planning / Dashboard

KmProd is interfaced and synced with your ERP, from which all the

necessary data is retrieved. It therefore allows multiple approvals for

your offices including:

• A complete IS system

• Production planning

• Analytical Dashboards to measure your performance

• Production scheduling

• An item database

• Shipment management

• Machine planning

• Nomenclature

The production schedule is recalculated according to customer orders

to generate deadlines / screens.

R&D

KmProd generates feedback that is essential for quality

control and its improvement in research and development

services.

Thus the data collected makes it possible to generate

statistics useful for the creation of future products and services.

Summaries and reports can be easily issued to accompany

the orientation resulting from the field feedback.

Workshop Management

KmProd generates pending production orders, production history

and events on a dedicated screen for your workshop's staff and

operators. They can also see their performance.

KmProd allows the operator to know where it is in production and

what to do.

The machine screen allows real-time supervision of machine

operation, as well as the implementation of preventive

maintenance to save time.

Packaging

KmProd simplifies your production packaging process

thanks to a dedicated module.

A workshop screen allows the operator to know exactly

the stage his/her production process , what product is

to be made and how to pack it. The detailed vision of

the production process enables your team to identify

where improvement is needed to ensure the performance

possible.

The arrival of components from the same order is planned,

to avoid stocking products on site and to promote the

almost immediate shipment of orders.

Staff Management

KmProd ensures HR management within the workshop:

• Team planning by the workshop manager

• Workshop screen with input by the worker

• Event management (RTT, breaks, etc.)

• Calculation and analysis of worker performance

Machines

Machines are there to free you from time and constraints, not the other way around. Find out how KmProd fits into the heart of your performance.

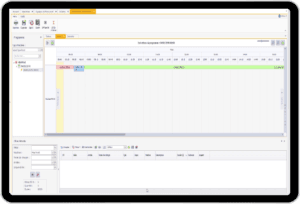

Production planning / Dashboard

KmProd is interfaced and synced with your ERP, from which all the

necessary data is retrieved. It therefore allows multiple approvals for

your offices including:

• A complete IS system

• Production planning

• Analytical Dashboards to measure your performance

• Production scheduling

• An item database

• Shipment management

• Machine planning

• Nomenclature

The production schedule is recalculated according to customer orders

to generate deadlines / screens.

Kiln Management

KmProd is connected to your workshop equipment and can

give oven heating instructions.

It allows an analysis of the performance of the use of the ovens,

in order to achieve energy savings by optimizing the heating

time based on planned production.

Billet Cutting

KmProd integrates an industrial intelligence module called

OptiPress which makes it possible to determine and calculate

the aluminum spinning instructions, and which optimizes the

cutting from the first cut of the billets.

It thus allows a reduction in rejects, and in the processing time.

It therefore allows savings at all scales !

Press supervision

The KmProd solution allows complete control and supervision

of the press, in order to ensure that production is as efficient as

possible.

While fully knowing the state and operation of production tools

to be able to analyze its performance.

• Computer Assisted Maintenance Management

• Organizational planning and forecasting

• Intuitive and improved maintenance planning

• Cost reduction

• Optimization of intervention times and times

• Extended equipment life expectancy

• Requests for automatic intervention

Camera Labeling

A camera recognition system identifies the shape of

the incoming profile, the correct label can then be

stuck on the product.

The error rate is drastically reduced thanks to process

automation, which also leads to significant increase

in performance.

Materials

Materials are rare and precious. Managing it efficiently is a guarantee of performance and environmental responsibility. KmProd is the ideal tool to link the two.

Production planning / Dashboard

KmProd is interfaced and synced with your ERP, from which all the

necessary data is retrieved. It therefore allows multiple approvals for

your offices including:

• A complete IS system

• Production planning

• Analytical Dashboards to measure your performance

• Production scheduling

• An item database

• Shipment management

• Machine planning

• Nomenclature

The production schedule is recalculated according to customer orders

to generate deadlines / screens.

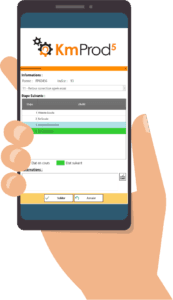

Supply Chain

KmProd allows the traceability of supplies at all scales:

Each billet is entered in the database and its position in

real time is visible on the application. KmProd helps

forecast and plan future supply needs based on

production. This effectively saves time as well as enables

a more fluid production process by limiting the storage of

billets.

Stocks

Our tool makes it possible to easily manage stocks by ensuring

a simple traceability of billets, according their suppliers, alloys,

castings, etc. It also enables you and your team to manage in real

time the filling of the various storage yards.

The calculation of your supply needs by KmProd is performed by

taking into account your planned production. Thus it allows a more

effective and fluid storage process. As we all know, a part that has

been ordered too early needs to be stored for too long, resulting in

a useless and costly waste of time and space.

Quality control and rejects

KmProd makes it possible to limit rejects by optimizing offcuts

during cutting, and by automating quality control. But also to

analyze the quality performance (quality synthesis).

The rejects which are therefore limited and may be recycled

more easily, which allows savings at all levels.

Subcontractor management

Our solution allows a simplified management of

contractors (logistics and / or industrial subcontracting).

The products are traceable throughout the process and

the organization is improved which saves time, lower losses,

and organized storage of finished or semi-finished products.

Camera Labeling

A camera recognition system identifies the shape of

the incoming profile, the correct label can then be

stuck on the product.

The error rate is drastically reduced thanks to process

automation, which also leads to significant increase

in performance.

Packaging

KmProd simplifies your production packaging process

thanks to a dedicated module.

A workshop screen allows the operator to know exactly

the stage his/her production process , what product is

to be made and how to pack it. The detailed vision of

the production process enables your team to identify

where improvement is needed to ensure the performance

possible.

The arrival of components from the same order is planned,

to avoid stocking products on site and to promote the

almost immediate shipment of orders.

Shipping and weighing

KmProd ensures the traceability of billet supplies until the

shipment of the profiles.

The management of the shipment is done by a schedule

shared with the transport subcontractor, which sends the

notifications to the customers who are waiting for their order.

The weighing of trucks before their departure can be carried

out to ensure a final check of the weight to avoid any errors

and save time.

Energy

Energy is a lever for growth if it’s well managed. KmProd integrates with your energy reality and helps you make the best decisions.

KmEnergy saves energy.

The tool shows where energy is lost.

• Water leak

• Heat loss

• Air conditioning

• Co2

• Overconsumption of electricity

Detection performed via machine learning algorithms

and analysis of energetic performance.

Business specific

Each plant is unique, each business is specific. KmProd adapts to your challenges and ambitions, giving you the best indicators and KPIs.

Commercial services - Online orders

KmProd scheduling gives your commercial department the neccesary monitoring

tools to check that production and delivery deadlines agreed upon with other

business units and clients are met. This will reassure your clients and will be one of

your major sales thus constituting a major sales argument.

KmProd offers an online ordering service for your customers. Orders are then

directly integrated into the KmProd system. Thus, you can offer your customers

reliable tracking solutions for their merchandise, as well as help them meet instant

deadlines.

Kiln Management

KmProd is connected to your workshop equipment and can

give oven heating instructions.

It allows an analysis of the performance of the use of the ovens,

in order to achieve energy savings by optimizing the heating

time based on planned production.

Tool Store

• Production instructions / technical parameters

• Management and evaluation of supply chain suppliers

• Performance and condition

• Management of the chain furnace

• Adjustments / Maintenance / Tests

• KPI: Life expectancy, number of tests ...

• Store management

Press supervision

The KmProd solution allows complete control and supervision

of the press, in order to ensure that production is as efficient as

possible.

While fully knowing the state and operation of production tools

to be able to analyze its performance.

OptiPresse

OptiPresse is an industrial intelligence module that calculates

and determines the most efficient spinning instructions.

• Unique repository

• Artificial Intelligence

• Return on investment by reducing costs and waste.

Management of the income furnace

KmProd connects to the workshop equipment and can

give instructions for heating the furnaces.

It allows an analysis of the performance of the use of the

furnaces, in order to achieve energy savings by optimizing

time of heating according to the planned production.

Container management

KmProd integrates a container management module enabling

real time efficient localization.

Each container is weighed to ensure that the content is the right

one, the characteristics of the profiles are directly associated with

the tool and are visible on the screen.

Avoiding errors will save time and improve your organizational

processes.

Equipment

KmProd allows you to forecast and plan which accessories

and equipment are going to be used in production.

This optimizes the load on the production line and saves

time for future operations.

Anodization

KmProd anodization makes it possible to manage what

type of product will be used for the anodization of the

profiles.

Based on Machine Learning and the industrial

intelligence algorithms developed by KmProd, the

anodization schedule optimizes deadlines and

increases productivity.

Lacquering

KmProd lacquering makes it possible forecast which type of

paint will be used to optimize the process and thus save time.

The lacquering schedule is organized by color shade, enabling

the optimiziation of the time allocated to the cleaning of cabins :

for example the light tones in one cab and the dark ones in the

other, the two cabins are therefore never cleaned at the same time!

This makes it possible to maximize the lacquering time of the profiles.

Foundry

KmProd allows you to monitor the entire production

flow of your workshop, starting from the foundry.

• Foundry Management

• Recycling of scrap

• Traceability of raw materials throughout the whole

production flow, according to metallurgical characteristics

Infography complete

Commercial services -

Online orders

KmProd scheduling gives your commercial

department the neccesary monitoring tools

to check that production and delivery

deadlines agreed upon with other business

units and clients are met. This will reassure

your clients and will be one of your major

sales thus constituting a major sales argument.

KmProd offers an online ordering service for

your customers. Orders are then directly

integrated into the KmProd system. Thus,

you can offer your customers reliable tracking

solutions for their erchandise, as well as help

them meet instant deadlines.

Production planning /

Dashboard

KmProd is interfaced and synced with

your ERP, from which all the necessary

data is retrieved. It therefore allows multiple

approvals for your offices including:

• A complete IS system

• Production planning

• Analytical Dashboards to measure your

performance

• Production scheduling

• An item database

• Shipment management

• Machine planning

• Nomenclature

The production schedule is recalculated

according to customer orders to generate

deadlines / screens.

Supply Chain

KmProd allows the traceability of supplies at

all scales:

Each billet is entered in the database and its

position in real time is visible on the application.

KmProd helps forecast and plan future supply

needs based on production. This effectively

saves time as well as enables a more fluid

production process by limiting the storage of

billets.

Stocks

Our tool makes it possible to easily manage

stocks by ensuring a simple traceability of billets,

according their suppliers, alloys, castings, etc.

It also enables you and your team to manage

in real time the filling of the various storage yards.

The calculation of your supply needs by KmProd

is performed by taking into account your planned

production. Thus it allows a more effective and

fluid storage process. As we all know, a part that

has been ordered too early needs to be stored

for too long, resulting in a useless and costly waste

of time and space.

Kiln Management

KmProd is connected to your workshop equipment

and can give oven heating instructions.

It allows an analysis of the performance of the use

of the ovens, in order to achieve energy savings by

optimizing the heating time based on planned

production.

Billet Cutting

KmProd integrates an industrial intelligence

module called OptiPress which makes it possible

to determine and calculate the aluminum

spinning instructions, and which optimizes the

cutting from the first cut of the billets.

It thus allows a reduction in rejects, and in the

processing time.

It therefore allows savings at all scales !

Tool Store

• Production instructions / technical parameters

• Management and evaluation of supply chain

suppliers

• Performance and condition

• Management of the chain furnace

• Adjustments / Maintenance / Tests

• KPI: Life expectancy, number of tests ...

• Store management

Press supervision

The KmProd solution allows complete control

and supervision of the press, in order to ensure

that production is as efficient as possible.

While fully knowing the state and operation of

production tools to be able to analyze its

performance.

OptiPresse

OptiPresse is an industrial intelligence module

that calculates and determines the most

efficient spinning instructions.

• Unique repository

• Artificial Intelligence

• Return on investment by reducing costs and

waste.

• Computer Assisted Maintenance Management

• Organizational planning and forecasting

• Intuitive and improved maintenance planning

• Cost reduction

• Optimization of intervention times and times

• Extended equipment life expectancy

• Requests for automatic intervention

KmEnergy saves energy.

The tool shows where energy is lost.

• Water leak

• Heat loss

• Air conditioning

• Co2

• Overconsumption of electricity

Detection performed via machine learning

algorithms and analysis of energetic performance.

R&D

KmProd generates feedback that is essential

for quality control and its improvement in

research and development services.

Thus the data collected makes it possible to

generate statistics useful for the creation of

future products and services.

Summaries and reports can be easily issued

to accompany the orientation resulting from

the field feedback.

Workshop Management

KmProd generates pending production orders,

production history and events on a dedicated

screen for your workshop's staff and operators.

They can also see their performance.

KmProd allows the operator to know where it

is in production and what to do.

The machine screen allows real-time supervision

of machine operation, as well as the

implementation of preventive maintenance to

save time.

Quality control and rejects

KmProd makes it possible to limit rejects by

optimizing offcuts during cutting, and by

automating quality control. But also to analyze

the quality performance (quality synthesis).

The rejects which are therefore limited and

may be recycled more easily, which allows

savings at all levels.

Management of the income furnace

KmProd connects to the workshop equipment

and can give instructions for heating the furnaces.

It allows an analysis of the performance of the

use of the furnaces, in order to achieve energy

savings by optimizing time of heating according

to the planned production.

Subcontractor management

Our solution allows a simplified management

of contractors (logistics and / or industrial

subcontracting).

The products are traceable throughout the

process and the organization is improved

which saves time, lower losses, and organized

storage of finished or semi-finished products.

Container management

KmProd integrates a container management

module enabling real time efficient localization.

Each container is weighed to ensure that the

content is the right one, the characteristics of the

profiles are directly associated with the tool and

are visible on the screen.

Avoiding errors will save time and improve your

organizational processes.

Equipment

KmProd allows you to forecast and plan which

accessories and equipment are going to be

used in production.

This optimizes the load on the production line

and saves time for future operations.

Anodization

KmProd anodization makes it possible to

manage what type of product will be used

for the anodization of the profiles.

Based on Machine Learning and the industrial

intelligence algorithms developed by KmProd,

the anodization schedule optimizes deadlines

and increases productivity.

Lacquering

KmProd lacquering makes it possible forecast

which type of paint will be used to optimize

the process and thus save time.

The lacquering schedule is organized by color

shade, enabling the optimiziation of the time

allocated to the cleaning of cabins : for

example the light tones in one cab and the

dark ones in the other, the two cabins are

therefore never cleaned at the same time !

This makes it possible to maximize the lacquering

time of the profiles.

Camera Labeling

A camera recognition system identifies the

shape of the incoming profile, the correct

label can then be stuck on the product.

The error rate is drastically reduced thanks

to process automation, which also leads to

significant increase in performance.

Packaging

KmProd simplifies your production packaging

process thanks to a dedicated module.

A workshop screen allows the operator to

know exactly the stage his/her production

process , what product is to be made and how

to pack it. The detailed vision of the production

process enables your team to identify where

improvement is needed to ensure the

performance possible.

The arrival of components from the same order

is planned, to avoid stocking products on site

and to promote the almost immediate shipment

of orders.

Shipping and weighing

KmProd ensures the traceability of billet

supplies until the shipment of the profiles.

The management of the shipment is done

by a schedule shared with the transport

subcontractor, which sends the notifications

to the customers who are waiting for their order.

The weighing of trucks before their departure

can be carried out to ensure a final check of

the weight to avoid any errors and save time.

Staff Management

KmProd ensures HR management within the

workshop:

• Team planning by the workshop manager

• Workshop screen with input by the worker

• Event management (RTT, breaks, etc.)

• Calculation and analysis of worker performance

Foundry

KmProd allows you to monitor the entire production

flow of your workshop, starting from the foundry.

• Foundry Management

• Recycling of scrap

• Traceability of raw materials throughout the whole

production flow, according to metallurgical

characteristics

Human

At the heart of your business and your intelligence, people are at the heart of KmProd’s approach to efficiency.

Production planning /

Dashboard

KmProd is interfaced and synced with

your ERP, from which all the necessary

data is retrieved. It therefore allows multiple

approvals for your offices including:

• A complete IS system

• Production planning

• Analytical Dashboards to measure your

performance

• Production scheduling

• An item database

• Shipment management

• Machine planning

• Nomenclature

The production schedule is recalculated

according to customer orders to generate

deadlines / screens.

R&D

KmProd generates feedback that is essential

for quality control and its improvement in

research and development services.

Thus the data collected makes it possible to

generate statistics useful for the creation of

future products and services.

Summaries and reports can be easily issued

to accompany the orientation resulting from

the field feedback.

Workshop Management

KmProd generates pending production orders,

production history and events on a dedicated

screen for your workshop's staff and operators.

They can also see their performance.

KmProd allows the operator to know where it

is in production and what to do.

The machine screen allows real-time supervision

of machine operation, as well as the

implementation of preventive maintenance to

save time.

Workshop Management

KmProd generates pending production orders,

production history and events on a dedicated

screen for your workshop's staff and operators.

They can also see their performance.

KmProd allows the operator to know where it

is in production and what to do.

The machine screen allows real-time supervision

of machine operation, as well as the

implementation of preventive maintenance to

save time.

Staff Management

KmProd ensures HR management within the

workshop:

• Team planning by the workshop manager

• Workshop screen with input by the worker

• Event management (RTT, breaks, etc.)

• Calculation and analysis of worker performance

Machines

Machines are there to free you from time and constraints, not the other way around. Find out how KmProd fits into the heart of your performance.

Production planning /

Dashboard

KmProd is interfaced and synced with

your ERP, from which all the necessary

data is retrieved. It therefore allows multiple

approvals for your offices including:

• A complete IS system

• Production planning

• Analytical Dashboards to measure your

performance

• Production scheduling

• An item database

• Shipment management

• Machine planning

• Nomenclature

The production schedule is recalculated

according to customer orders to generate

deadlines / screens.

Kiln Management

KmProd is connected to your workshop equipment

and can give oven heating instructions.

It allows an analysis of the performance of the use

of the ovens, in order to achieve energy savings by

optimizing the heating time based on planned

production.

Billet Cutting

KmProd integrates an industrial intelligence

module called OptiPress which makes it possible

to determine and calculate the aluminum

spinning instructions, and which optimizes the

cutting from the first cut of the billets.

It thus allows a reduction in rejects, and in the

processing time.

It therefore allows savings at all scales !

Press supervision

The KmProd solution allows complete control

and supervision of the press, in order to ensure

that production is as efficient as possible.

While fully knowing the state and operation of

production tools to be able to analyze its

performance.

• Computer Assisted Maintenance Management

• Organizational planning and forecasting

• Intuitive and improved maintenance planning

• Cost reduction

• Optimization of intervention times and times

• Extended equipment life expectancy

• Requests for automatic intervention

Camera Labeling

A camera recognition system identifies the

shape of the incoming profile, the correct

label can then be stuck on the product.

The error rate is drastically reduced thanks

to process automation, which also leads to

significant increase in performance.

Materials

Materials are rare and precious. Managing it efficiently is a guarantee of performance and environmental responsibility. KmProd is the ideal tool to link the two.

Production planning /

Dashboard

KmProd is interfaced and synced with

your ERP, from which all the necessary

data is retrieved. It therefore allows multiple

approvals for your offices including:

• A complete IS system

• Production planning

• Analytical Dashboards to measure your

performance

• Production scheduling

• An item database

• Shipment management

• Machine planning

• Nomenclature

The production schedule is recalculated

according to customer orders to generate

deadlines / screens.

Supply Chain

KmProd allows the traceability of supplies at

all scales:

Each billet is entered in the database and its

position in real time is visible on the application.

KmProd helps forecast and plan future supply

needs based on production. This effectively

saves time as well as enables a more fluid

production process by limiting the storage of

billets.

Stocks

Our tool makes it possible to easily manage

stocks by ensuring a simple traceability of billets,

according their suppliers, alloys, castings, etc.

It also enables you and your team to manage

in real time the filling of the various storage yards.

The calculation of your supply needs by KmProd

is performed by taking into account your planned

production. Thus it allows a more effective and

fluid storage process. As we all know, a part that

has been ordered too early needs to be stored

for too long, resulting in a useless and costly waste

of time and space.

Quality control and rejects

KmProd makes it possible to limit rejects by

optimizing offcuts during cutting, and by

automating quality control. But also to analyze

the quality performance (quality synthesis).

The rejects which are therefore limited and

may be recycled more easily, which allows

savings at all levels.

Subcontractor management

Our solution allows a simplified management

of contractors (logistics and / or industrial

subcontracting).

The products are traceable throughout the

process and the organization is improved

which saves time, lower losses, and organized

storage of finished or semi-finished products.

Camera Labeling

A camera recognition system identifies the

shape of the incoming profile, the correct

label can then be stuck on the product.

The error rate is drastically reduced thanks

to process automation, which also leads to

significant increase in performance.

Packaging

KmProd simplifies your production packaging

process thanks to a dedicated module.

A workshop screen allows the operator to

know exactly the stage his/her production

process , what product is to be made and how

to pack it. The detailed vision of the production

process enables your team to identify where

improvement is needed to ensure the

performance possible.

The arrival of components from the same order

is planned, to avoid stocking products on site

and to promote the almost immediate shipment

of orders.

Shipping and weighing

KmProd ensures the traceability of billet

supplies until the shipment of the profiles.

The management of the shipment is done

by a schedule shared with the transport

subcontractor, which sends the notifications

to the customers who are waiting for their order.

The weighing of trucks before their departure

can be carried out to ensure a final check of

the weight to avoid any errors and save time.

Energy

Energy is a lever for growth if it’s well managed. KmProd integrates with your energy reality and helps you make the best decisions.

KmEnergy saves energy.

The tool shows where energy is lost.

• Water leak

• Heat loss

• Air conditioning

• Co2

• Overconsumption of electricity

Detection performed via machine learning

algorithms and analysis of energetic performance.

Business specific

Each plant is unique, each business is specific. KmProd adapts to your challenges and ambitions, giving you the best indicators and KPIs.

Commercial services -

Online orders

KmProd scheduling gives your commercial

department the neccesary monitoring tools

to check that production and delivery

deadlines agreed upon with other business

units and clients are met. This will reassure

your clients and will be one of your major

sales thus constituting a major sales argument.

KmProd offers an online ordering service for

your customers. Orders are then directly

integrated into the KmProd system. Thus,

you can offer your customers reliable tracking

solutions for their erchandise, as well as help

them meet instant deadlines.

Kiln Management

KmProd is connected to your workshop equipment

and can give oven heating instructions.

It allows an analysis of the performance of the use

of the ovens, in order to achieve energy savings by

optimizing the heating time based on planned

production.

Tool Store

• Production instructions / technical parameters

• Management and evaluation of supply chain

suppliers

• Performance and condition

• Management of the chain furnace

• Adjustments / Maintenance / Tests

• KPI: Life expectancy, number of tests ...

• Store management

Press supervision

The KmProd solution allows complete control

and supervision of the press, in order to ensure

that production is as efficient as possible.

While fully knowing the state and operation of

production tools to be able to analyze its

performance.

OptiPresse

OptiPresse is an industrial intelligence module

that calculates and determines the most

efficient spinning instructions.

• Unique repository

• Artificial Intelligence

• Return on investment by reducing costs and

waste.

Management of the income furnace

KmProd connects to the workshop equipment

and can give instructions for heating the furnaces.

It allows an analysis of the performance of the

use of the furnaces, in order to achieve energy

savings by optimizing time of heating according

to the planned production.

Container management

KmProd integrates a container management

module enabling real time efficient localization.

Each container is weighed to ensure that the

content is the right one, the characteristics of the

profiles are directly associated with the tool and

are visible on the screen.

Avoiding errors will save time and improve your

organizational processes.

Equipment

KmProd allows you to forecast and plan which

accessories and equipment are going to be

used in production.

This optimizes the load on the production line

and saves time for future operations.

Anodization

KmProd anodization makes it possible to

manage what type of product will be used

for the anodization of the profiles.

Based on Machine Learning and the industrial

intelligence algorithms developed by KmProd,

the anodization schedule optimizes deadlines

and increases productivity.

Lacquering

KmProd lacquering makes it possible forecast

which type of paint will be used to optimize

the process and thus save time.

The lacquering schedule is organized by color

shade, enabling the optimiziation of the time

allocated to the cleaning of cabins : for

example the light tones in one cab and the

dark ones in the other, the two cabins are

therefore never cleaned at the same time !

This makes it possible to maximize the lacquering

time of the profiles.

Foundry

KmProd allows you to monitor the entire production

flow of your workshop, starting from the foundry.

• Foundry Management

• Recycling of scrap

• Traceability of raw materials throughout the whole

production flow, according to metallurgical

characteristics