Over 30 years of experience in Industrial Intelligence

For over 30 years, KmProd has been at the forefront of industrial transformation. Our state-of-the-art software solutions are designed to propel production shops into the Industry 4.0 era. At META 2i, we combine our expertise in process supervision and software development to offer production monitoring and MES (Manufacturing Execution System) tools tailored to your needs.

Transform your operations, optimize your performance and make key decisions with precision. Join the industrial revolution with KmProd – where innovation and excellence meet to shape the future of your business.

Operational Excellence and Industrial Innovation

Reinvent your production with KmProd: in-depth expertise and cutting-edge solutions for unprecedented industrial performance.

Our Mission

Helping industrial clients and manufacturers achieve operational excellence by providing them the process monitoring and continuous improvement tools they need.

Our Expertise

We have developed an unmatched expertise in manufacturing process optimization by serving industrial clients for over 30 years. This has enabled us to conceive a unique range of consulting services and MES software packages, edited and developed by our experts.

Our Toolkit

Our toolkit integrates the development of specific business modules adapted to the existing manufacturing process, while creating the foundation for new systems. These modules enable a smoother communication between the operator and the supervisors resulting in the significant improvement of the manufacturing information system, be it in a factory or a production workshop.

Your Processes, Our Job

Satisfying your customers requires you to innovate and to make sure that your quality improvement processes are on the right track. You need to adapt constantly to your client’s evolving needs.

This is why agility lies at the heart of our business

○ Real-time data

○ Operational data exploitation

○ Process optimization

○ Measurement

○ Management

○ Improvement

○ Centralizing data and functions

○ Enabling cross-system communication

○ Improving information distribution

○ Fostering service integration

KmProd Benefits

Like the majority of our customers, we have an industrial background. Our expertise comes from three decades working for our customers’ factories. We are passionate about industrial processes and this is what connects us to our clients. We stand by them to ease the evolution of their core businesses and operational processes.

○ Supply chain management

○ Management of the 4 resources of the company (HR, Energy, Machinery, Materials)

○ Lean management companion

○ Industrial and energy OPTIMIZATION

○ Continuous improvement of your processes

○ Multi-sites management software with multi-language capabilities

○ SDK (Software Development Kit) for product improvement

○ Edition of an industrial software suite for production monitoring (KmProd)

○ Creation of customized solutions, modules, and MES/MOM applications

○ Development in industrial computing in compliance with market standards

○ Integration of process supervision applications (SCADA)

○ Revamping of software, applications, and systems

○ Systems integration

○ Technical and application training (certified training center)

○ Consulting and auditing of production sites

○ Engineering studies and industrial project management

○ Online remote application management

Business Support:

○ Auditing/ Engineering/ Expertise/ Consulting

○ Study/Analysis

○ Customized development

○ Application management

Partnership:

○ Systems integrators

○ Third-party system editors

○ Schools, universities and research centers

KmProd’s ROI

The return on investment (ROI) of KmProd is real and multidimensional.

Here are some of KmProd’s main benefits:

1

Waste & Scrap Reduction

Reducing waste is essential to keep your production costs under control as well as your organization.

2

Improved Business Processes

Each production workshop is unique and each product has its own specific processes.

Our toolkit integrates and manages your 4 main resources (HR, Machine, Material, Energy) in all of their dimensions (time, delays, duration, priority, prevention).

3

Less Raw Material

Reducing your consumption of raw material is essential for your cost management. It is also a strong action to preserve our planet!

4

Energy Optimization

Our energy optimization module adapts to your daily operational challenges and enables you to make sustainable savings.

Have your indicators ever generated errors ?

A company’s success is largely based on its information system.

META 2i’s MES/MOM KmProd5 solution provides the technical tools you need. It ensures a highly accurate assesment of your operations and the efficiency of your teams. How to limit errors, scraps, delays and give yourself and your team some peace of mind ?

You can rely on KmProd5 to aqcuire accurate information !

Indicate

Are your indicators reliable and accurate? Have they ever generated errors ?

Monitor and Operate

If you cannot measure accurately, your decisions risks being distorted and misguided by inadequate information.

Interpreting Operational Data

Bad decision-making usually originate from inacurrated data needing to massive error generation, KmProd5 will help you prevent that type of mistakes.

Improving Efficiency

Relying on an accurate and updated overview of your workshop’s performances will help your teams improve their efficiency.

KmProd in Figures

Through a history rich in innovation and technological adaptation, KmProd has established itself as a forerunner of Industry 4.0. More than software, it’s constant evolution at the heart of your production. Here are a few key figures that illustrate our commitment to excellence and innovation:

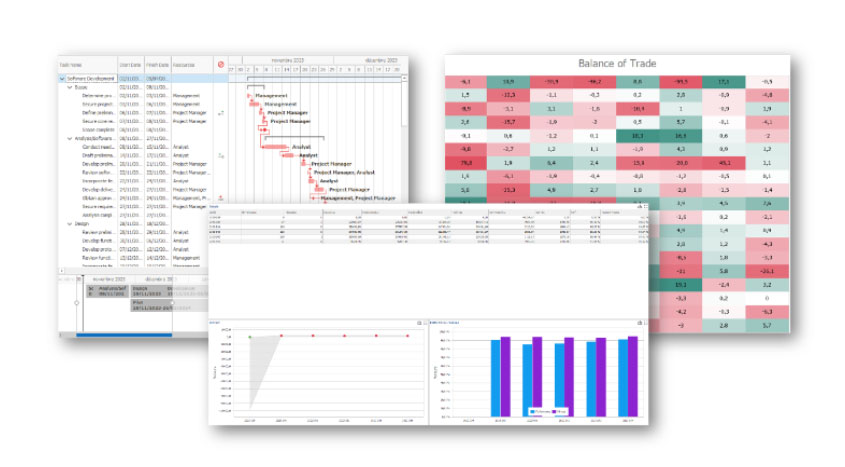

KmProd version 5.6: The Era of Innovation

Dive into the heart of innovation with the latest version of KmProd – 5.6.

Designed to exceed your expectations in terms of performance, this revolutionary update combines sleek design, intuitive ergonomics, improved speed, and enhanced security.

Discover how KmProd version 5.6, enriched with advanced features and an optimized user interface, can transform your production management.

Our experts are there for you

Request a demo !