About KmProd

KmProd method

Our history and values

Human at the heart of innovation

We know that your profession is demanding and that each workshop has its unique specificities, that’s why the KmProd method integrates from the start all the stakeholders.

Continuous improvement is at the heart of our DNA and will remain so for us to grow with and for our customers.

Our goals for our customers

The KmProd method is designed to meet the problems experienced by our customers every day.

Our response, tools and metrics (KPI) are based on these goals and we are continually seeking to improve them.

Limit rejects and losses

Economic and ecological gesture, optimized management of the risk of rejects is essential.

Organize

Your business evolves quickly and technologies even more. The scheduling and organization allow to go to the essential without upsetting the existing.

Share information

Whether rising, descending or horizontal, information is at the heart of your strategy and your success.

Optimize

Continuous adaptation to market requirements and the needs of the field can only be achieved by taking into account the realities of the organization.

How do we work?

Subject progress tracking will be performed in PDCA (Plan, Do, Check, Act).

This method presents the 4 phases to successively follow in a logic of continuous improvement.

capturing and mesuring

network

synthesize and decide

Lean Management Support

The lean management methodologies have been proven in the industry, our tools allow to integrate these processes and devices in your daily life.

1

Define

Implementation of measurement indicators (KPI - Key Performance Indicator, objectives).

2

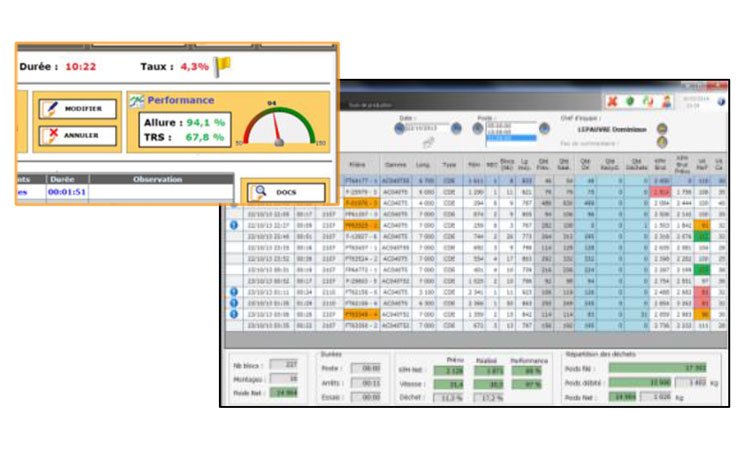

Measure

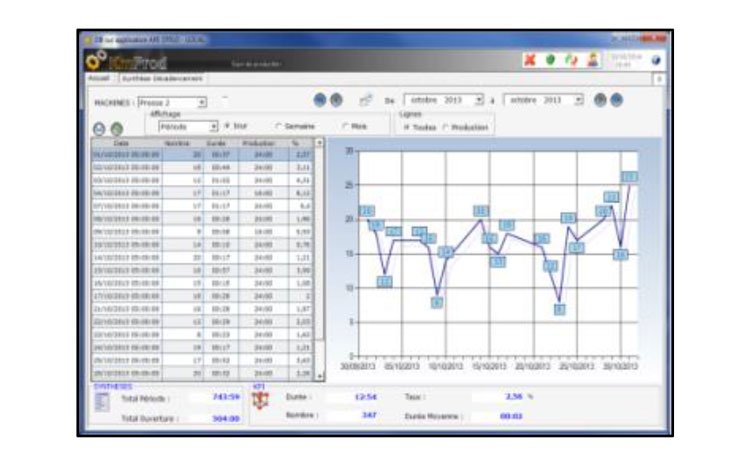

Visual management via the dashboard. Real time display, identification of delays and drifts.

3

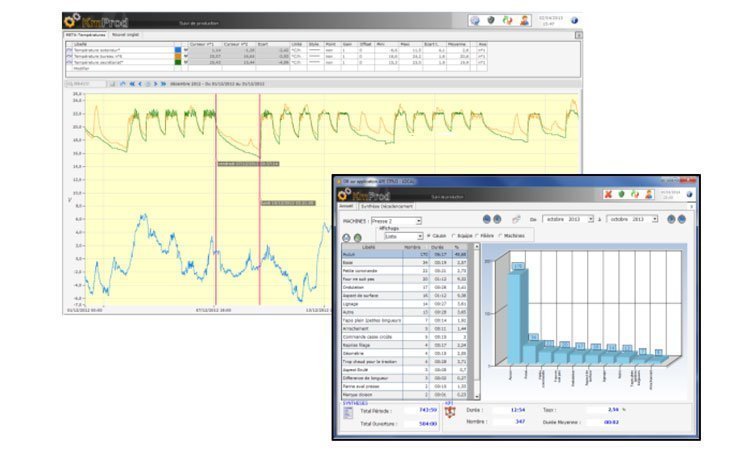

Analyse

Exploitation of the data and statistics of synteses. Multi-decision tools, display curves in real time.

4

Act

Execute the action plan. Real-time traffic information (schedules, imagery, logistics, materials, consumables).

5

Control and Improve

Standardization of verification and quality control. Comparative expected / realized, syntheses for decision makers.

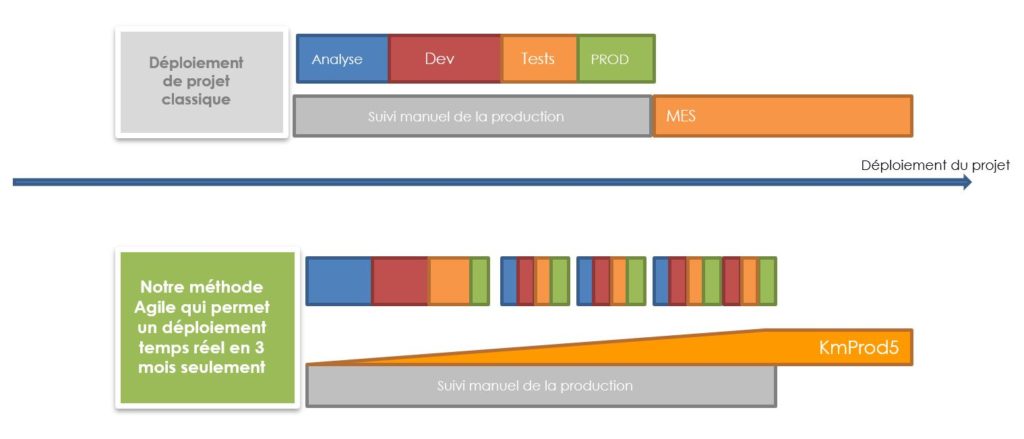

KmProd5 and Agile Methods

Agile methods have proven themselves and our many deployments have increased our expertise to the point of being able to quickly deploy complex solutions.

What are the advantages of your structure?

Modular and quick to deploy system. In just three months, the first modules can be installed and tested!

Real-time correction and adaptation during deployment. Fixes are applied as needed

Solution based on user experience, from workshop to decision.

Why an MES / MOM?

The MES / MOM is at the heart of the data and even more, it is a lever of growth and precision. Its ability to interface between the production terminals / sensors and the ERP (Enterprise Resource Planning) gives a fair and realistic vision of the production as the workshop.

The functions of the ERP: the Enterprise Resource Planning, is part of the normative, legal and commercial logic of the company. Its action is complementary to that of the MES / MOM.

- Planning de production

- Factory production schedule

- Logistics

The MES / MOM, at the heart of the data, is able to deploy many modules for the applicant. These tools allow synthesis during production for decision-makers and actors

- Acquisition of data

- Scheduling

- Staff management

- Resource Management

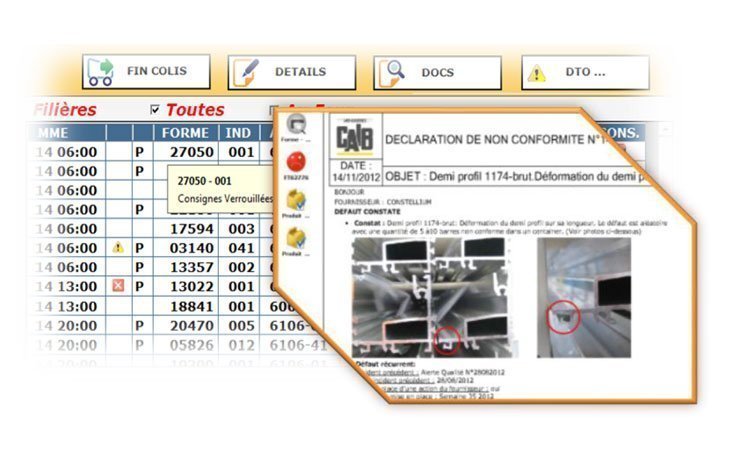

- Product and batch tracking

- Product and historical traceability

- Quality control

- Manufacturing process management

- Performance Analysis

- Document management

- Maintenance management

The MES / MOM communicates perfectly with the machines. It summarizes the information and makes it possible to anticipate risky situations (delays, reminders, warnings, requests for actions). This capability allows for effective action in the following areas:

- Manufacturing

- Machines and terminals

- Controllers

- Control and Quality